Advantages of prosthetics using dental crowns of zirconium oxide (zirconium dioxide)

Advantages of prosthetics using dental crowns of zirconium oxide (zirconium dioxide)

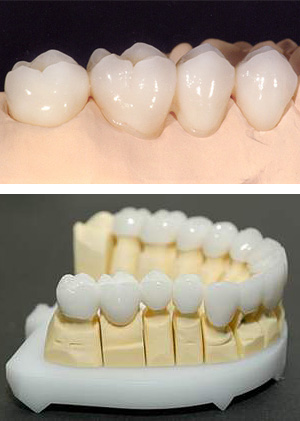

All the advantages of metal-free zirconium dental crowns are derived from the unique properties of the material – zirconium dioxide and from a radically new high-precision crown manufacturing techniques based on zirconium dioxide, abbreviated as CAD / CAM. Creating a non-metal crown based on CAD /CAM technology (computer-aided design/computer-aided manufacturing) fundamentally differs from the cermet manual casting. The impression made by the doctor is used to form a model to be scanned by laser followed by the computer-aided simulation of the future crown. The crown is made in two stages. At the first stage the frame is worked out at the milling machine from a single piece of zirconium oxide block, the frame shade is selected to suit the color of the tooth. Afterwards the frame is covered with a ceramic mass.

The unique properties of zirconium oxide (zirconia dioxide) for dental crown manufacturing:

- Light weight

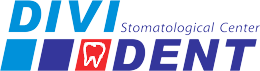

- Esthetics in prosthetic dentistry using zirconium crowns

- The frame of zirconium oxide crown is white and has a natural transparency and translucency of zirconia approximately equal to light transmission of natural tooth structure, and because of this feature zirconia crowns are not X-ray resistant.

- It is for the first time that the selection of color is carried out not only at the level of the ceramic coating, but also at the level of the frame. This allows for avoiding the effect of metal translucency.

- Steady color: zirconia crowns do not change color over time, even if the patient regularly drinks coffee and black tea.

- For denture coating high-strength ceramics is used. It has translucency, semitransparency and wide range of color-shades which allows for creating crowns, indistinguishable from natural teeth.

Biocompatibility in dental prosthetics using bits of zirconium oxide (zirconia)

- lack of any kind of allergic reactions to zirconia, even among people with allergies.

- Zirconium oxide is a hypoallergenic material, and is superior to any alloys, including gold due to its biocompatibility.

- No risk of oxidation conditioned by to the lack of metal molecules in the crown.

- Favorable clinical results are confirmed by histological (microscopic) studies: after six months of contact with the zirconium oxide based ceramics no pathological changes are revealed in the oral cavity.

Durability and comfort of teeth restoration with zirconium oxide (zirconium dioxide) crowns

- The thickness of zirconium oxide frame is just 0.4 mm. This allows for minimal cutting of teeth, as to crowns – they are much lighter than cermet. Zirconium oxide is characterized by a low thermal conductivity index, i.e. produces no response to hot or too cold food.

- In contrast to metal, zirconium oxide does not deform with time.

- By durability, zirconium oxide is as good as metal. New crowns will serve you for long!

- Enhanced durability allows producing single metal free crowns as well as extended bridgework prostheses, and even place such crowns on implants.

High aesthetics, durability and biocompatibility of zirconium oxide makes it ideal for all types of dentures.

Due to its physical and technical characteristics zirconium dioxide is used in implant-supported dentures, as well as natural teeth stump restoration, in the manufacturing of bridges, highly aesthetic microprothesis, etc.